Specification Validation

The stress of wondering whether a design will deliver the performance required within a new build or refurbishment can be eliminated using expertise within Gilberts Blackpool.

The stress of wondering whether a design will deliver the performance required within a new build or refurbishment can be eliminated using expertise within Gilberts Blackpool.

The independent air movement manufacturer offers techniques to simulate and test a ventilation design in advance of on-site installation.

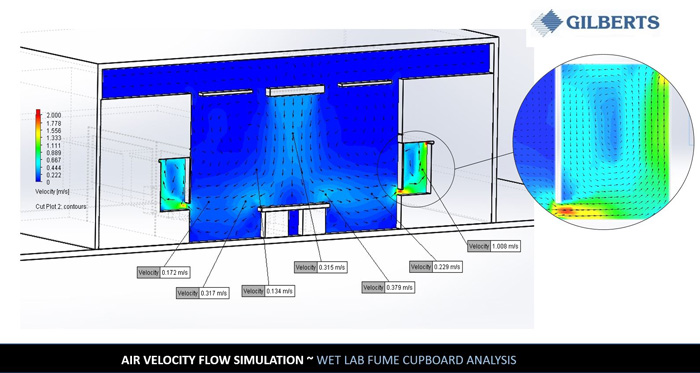

Using computation fluid dynamics (CFD) software, Gilberts says it can run the proposed ventilation/air movement design to validate its performance according to air changes, air quality, temperature. Appropriate adjustments can then be made to the strategy if required, and re-tested, to ensure the target performance criteria will be met once the ventilation is installed and the building occupied.

“The permutations affecting a ventilation strategy are almost infinite, so trying to execute all the necessary calculations and validate a strategy is time consuming, especially as other influencing factors in the building design may be changed along the way,” observes Ian Leonard, Gilberts R&D manager. “Our CFD is a cost-effective method to minimise or even eliminate- the need for costly prototypes, and can save significant amounts of time- and money- reworking a strategy by indicating where any potential weaknesses lie. It also enables consultants and contractors to test different theories and strategies at the design stage, to achieve the best value solution for each project.”

The CFD service is just part of Gilberts’ personal service, which includes in-house design and development of bespoke components, remodelling of standard products, and testing in its in-house laboratory.

Founded over 55 years ago, privately owned Gilberts is unique in air movement in its ability to design and manufacture in-house. All components are engineered to order within its 95,000 ft2 facility in Lancashire.