Fit for purpose?

A specification validation service has been developed to help ensure the practical and aesthetic longevity of screening louvres.

A specification validation service has been developed to help ensure the practical and aesthetic longevity of screening louvres.

Gilberts Blackpool – the independent manufacturer of screening and ventilation louvres ¬– has developed the service to enable specifiers to be assured, from the outset, that the material, finish and format of the louvres will deliver, within budget.

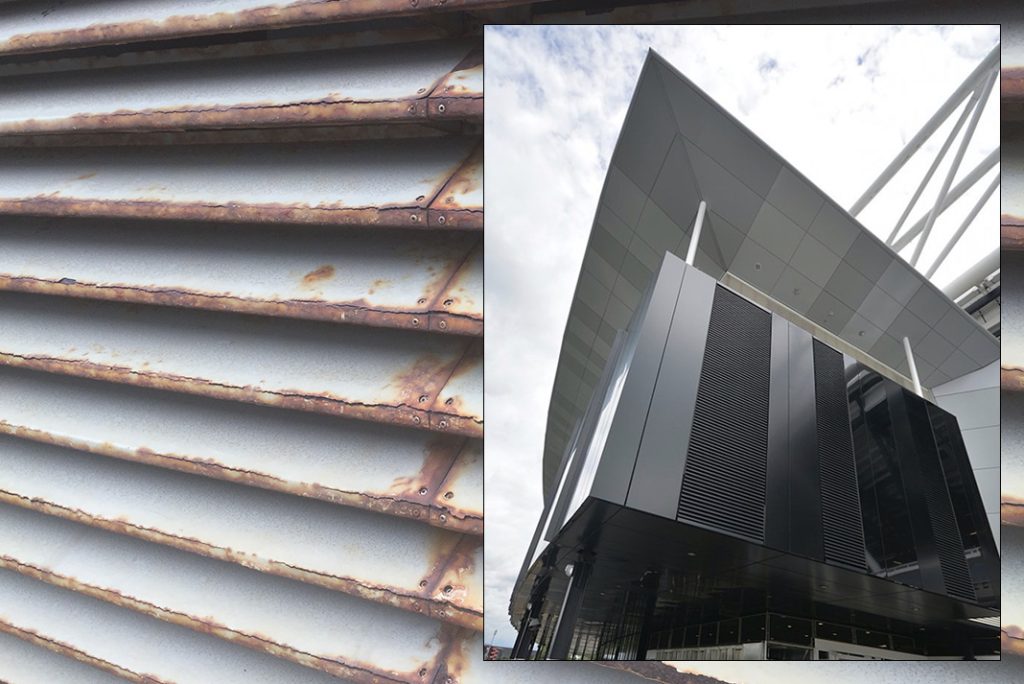

“So often, the aesthetics of the external façade, particularly the cladding, can be spoilt by rusting or peeling louvres,” said Ian Rogers, Gilberts sales director. “The issue is exacerbated as those louvres are often in inaccessible locations – high up on an elevation, on the roof. It could be avoided just by appropriate, suitable product specification at the outset. This includes considerations as simple as changing the material from steel to aluminium, the quality of the finish.”

Gilberts has developed its own louvre product range over the years to keep pace with the evolution of building design and structural interfaces. Thus, it now has ranges of standard, high performance, site-assembled and acoustic louvres, available in a range of ratings for weight, ventilation, weather, insects and even bird ingress. Even fixings can often be tailored to individual site preferences.

With its in-house design expertise, Gilberts says it has the capability to create bespoke configurations which can be both CFD-modelled and tested within its own laboratory to give customers complete ‘fit for purpose’ peace of mind.

Gilberts also offers a comprehensive range of PPC,PVF and PVF2 coatings across its louvres, available in any RAL colour, applied to louvres of almost any size.