Making better use of daylight

Solar panel on a red roof

Natural light is an architectural tool and the more it is used within buildings, the more we can reduce the amount of energy required for lighting, whilst also reducing energy usage for heating and cooling. Given that we spend so much time indoors, the design of buildings, and particularly the provision of daylight, is critical to our quality of life. However, with a vast array of glass and glazing solutions in the marketplace, there is a clear need for facade solutions that not only provide a desirable and comfortable place for occupants but also help architects achieve the best energy performance, minimise overall environmental impact, as well as providing the inspiration for aesthetically pleasing buildings.

Legislative changes and environmental regulations have also played a part in the need for higher levels of daylight in today’s buildings. As traditional glass facades can be costly and difficult to install, architects, clients and contractors have driven demand for a more versatile and cost-effective glazing system that could be applied to both walls and roofs.

For specifiers seeking thermal efficiency, airtightness, fire performance and aesthetic appeal, and installers requiring robust, easy-to-fit products with technical support on tap, Brett Martin has developed Marlon Clickfix1040 – a lightweight architectural glazing system manufactured from polycarbonate which can be used to create internal or external facades, roofs, cladding and partitioning.

Bright base for boats

To provide maximum natural daylight at the new multi-million pound yachting HQ in Portsmouth, which has been built to act as a focal point for the design, construction and development of yachts, Brett Martin was appointed to create a vertical glazing element for the installation on two of the elevations – and Clickfix was up for the challenge.

Setting benchmarks for sustainability and construction innovation, the stunning 6,874 m² building has been designed by HGP Architects and built by T. A. Colbourne to achieve a BREEAM rating of ‘Excellent’. The building includes a team headquarters for design work and training, boat building facilities and a public visitor centre with VIP hospitality. Utilising ultra-fast modern methods of construction that saw fit out start before the build base was complete, it features 432 solar PV panels, utilises 100% renewable electricity and has 15 separate building performance monitoring points.

The incorporation of natural light into the building was a key part of the sustainable design. With this natural resource now seen as crucial in low carbon construction, the project required two clear glazed facades on the south and east elevations. For a glazing system which would not only maximise daylight, but also offer exceptional airtightness, durability and UV stability, Marlon Clickfix1040 from Brett Martin proved the most thermally efficient solution and ensured a fast and straightforward installation for specialist contractor T. A. Colbourne.

Specified with glass diffusing technology, the polycarbonate panels provide a naturally diffused daylight. They also reduce solar glare, ensuring a comfortable interior environment in this landmark building. To further reduce the risk of solar glare, whilst helping the building almost double its thermal performance, a giant fabric wrap was selected to envelope much of the exterior facade. Its translucency still allows natural light into the interior of the building, whilst providing a sail-like canvas on to which the company can project graphics.

“The installation of Marlon Clickfix onto the south and east elevations will bring natural light into the building whilst helping to create a thermally efficient building envelope in line with the low carbon requirements,” commented Tim Bench, contracts manager at T.A. Colbourne. “The simple installation process meant we completed the elevations in just three weeks.”

Click and fix

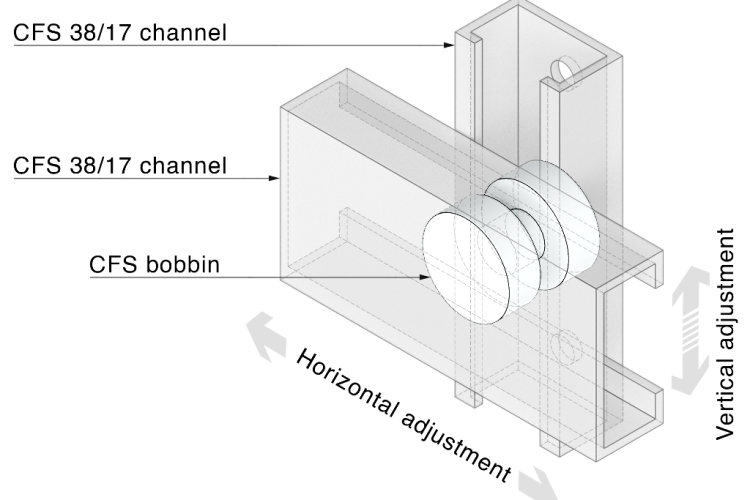

Central to the Marlon Clickfix system is the lightweight polycarbonate panel with integral interlocking connections that simply click into place to form glazed areas of unlimited size and shape. The 40 mm structured polycarbonate glazing panel has 10 insulating walls to achieve a U-value of 0.99 W/m²K, for a high performing and thermally efficient glazing solution. The Marlon Clickfix1040 system has a choice of two thermally broken aluminium glazing bar systems, depending on the application. The Marlon Clickfix VF glazing bar system has been specifically developed for vertical installations, such as facades, partitioning, rain screens and vertically glazed northlights, whilst Marlon Clickfix RL has been designed for use in low pitch rooflights and canopies.

Also available in a wide range of tints and colours, Marlon Clickfix provides high quality natural light, superior thermal insulation and UV protection. It is also lightweight and easy to handle, in addition to the impact resistance, resilience and structural strength that is inherent in all of Brett Martin’s high performance polycarbonate sheet products.

With the new multi-million pound HQ now complete, Brett Martin Daylight Systems, the only European company to manufacture rooflights in all the main rooflight glazing materials – polycarbonate, GRP and glass – has demonstrated once again that making better use of daylight is central to achieving the required performance of highly sustainable buildings.

[box type=”shadow” align=”alignleft” width=”200″ ]Contact details

Sandford Close

Aldermans Green Industrial Estate

Coventry

CV2 2QU

T: 0247 660 2022

W: www.brettmartin.com[/box]