Newton Waterproofing Gets Top Marks from London School of Economics

When principal contractor Mace Group needed an expert to waterproof a basement with more than 2,250m2 floor space at the world-renowned London School of Economics, they turned to Newton Waterproofing Systems to help.

With a unique Membrane Recycling Service, Newton appealed to Mace Group’s aim of becoming a net-zero carbon company in 2020. Coupled with expert technical advice, guaranteed waterproofing systems and Specialist Basement Contractor Cast Contracting Ltd (CCL), Newton was the perfect choice for the major project.

Designed by Grafton Architects, the school’s Marshall Building at 44 Lincoln’s Inn Field includes an extensive two-storey, mixed-use basement that will house plant areas, squash courts, changing facilities and a sports hall.

Newton Specialist Contractor CCL were appointed to design, supply and install the waterproofing, providing a completely dry, guaranteed solution by using the Newton CDM System.

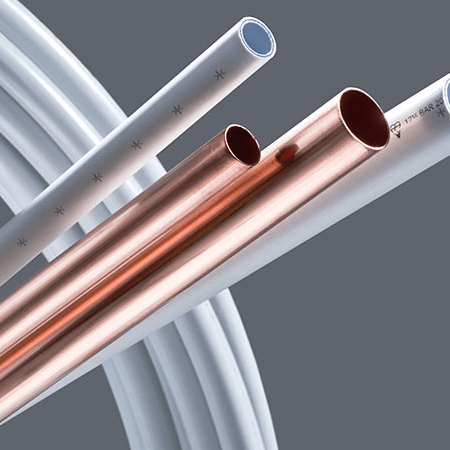

Otherwise known as Type C waterproofing, the CDM System is the safest and most reliable form of waterproofing and comprises of Cavity Drain Membranes, Drainage, Pumps and Control Systems.

Prior to installation, CCL applied Newton 906 Lime Inhibitor to the new slab to prevent free lime from the concrete from affecting the drainage membranes. The Type A liquid waterproofing membrane Newton 103-S was also applied internally to many of the concrete surfaces as a barrier to water.

With preparations complete, over 2,250m2 of Newton 520 eco membrane was installed to the floor and over 570m2 of Newton 508 membrane installed to the walls to create the Newton CDM System.

A drainage system of Newton Basedrain channels also directs any water captured by the membranes to the point of discharge, and the whole system was sealed with Newton OverTape.

The result was hugely impressive, and Newton Waterproofing’s Managing Director Warren Muschialli said: “The Newton CDM System is a combination of decades of basement waterproofing experience and the highest quality BBA certified cavity drain membranes from Newton System 500, and is the most reliable and maintainable waterproofing solution for any below ground space.

“Covering a total of 2,250m2 of floorspace presented a reasonable challenge for CCL and, despite requiring dedicated delivery slots and working to an extremely tight program of work, CCL were praised on the quality and speed of their installation, which was completed well within the deadline.”

What also made a lasting impression was Newton’s recycling service, which recycled 115 kg of HDPE waste, therefore preventing more than 132 kg of CO2 emissions.

Alice Ashpitel, Sustainability Manager at Mace Group, commented: “The unique closed-loop recycling service provided by Newton bought real benefits to this project. It has helped us reduce our construction waste and supported our Time to Act campaign to reduce single use plastic waste across construction, all with no impact on site activities.”

The closed-loop scheme works in collaboration with the company’s Specialist Basement Contractors, who are set up with tonne bags for storing offcuts of plastic membranes, which are then collected by Newton.

The virgin HDPE membrane is then processed and chipped into small granules at Newton’s headquarters in Tonbridge, Kent, before being collected by a national recycler who manufactures the granules into new products for the construction industry. Newton donate all profits made by the scheme to marine conservation charity Surfers Against Sewage.

“Our recycling scheme adds a huge amount of value to a project and we have won contracts on the strength of it. We’re delighted that Mace Group recognised the benefits of it,” added Warren.

For more information on Newton Waterproofing and the Newton Membrane Recycling Service, call 01732 360 095 or email info@newtonwaterproofing.co.uk.