School renewal

Allford Hall Monaghan Morris (AHMM) specified AluK’s curtain walling and window systems for the Burntwood School project, a series of new educational buildings which will serve up to 2,000 pupils and over 200 staff. The scheme, developed by architect AHMM, working in close partnership with Lend Lease, Wandsworth Borough Council and Burntwood School, will see 85% of the school rebuilt.

Collaborative meetings with AHMM and AluK project teams led to working on initial detailing for the scheme, creating bespoke curtain walling and window systems solutions that would accommodate not only the design, but also the performance and regulations requirements. An early collaboration ensured more speed and efficiency in a number of key areas, including the design, procurement, construction, maintenance, operation, and ultimately, decommissioning and recycling. Involving the manufacturer at the earliest stage helped ensure that performance requirements were met, which is especially important for when a bespoke design is being implemented. Such an approach also gives space to technical design improvement and innovation right from the design stage.

Attention to detail

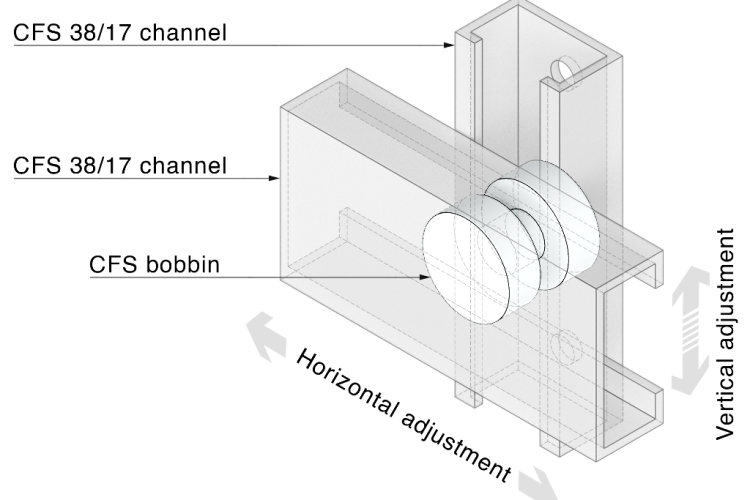

This collaborative process started with drawing details and typical sizes for project elements to establish whether the necessary project U-values could be achieved with cost savings on glazing specification. AluK’s 72BW HI window system and SG52 curtain walling system were supplied for the Curriculum Buildings, which forms the bulk of the accommodation for the school. The 72BW HI window system incorporates AluK’s Spidertechnology thermal breaks that allow high thermal insulation to be achieved without common expensive system enhancements. Certified under the ‘Secured by Design’ scheme, the 72BW HI window system integrates high security multipoint-locking systems. For the Performing Arts Building, the architects specified the SG52 and bespoke SL52 curtain walling systems.

Lower elements of the facade were set to incorporate the SG52 curtain walling system, and upper cantilevered elements of the building were to be glazed using SL52 capped system. AluK worked closely with the architects and the fabricator to establish exactly what design and detailing requirements were needed to ensure performance and aesthetic were attained. Daniel Lewis, senior architect at AHMM, comments: “For the project we required a bespoke solution for the fin face caps (145 x 15 mm top hat capping). AluK provided us with an excellent service – the company’s proactive approach as well as technical and design expertise meant that we were able to realise our designs.”

The design of the finned feature cap was created to travel the height and width of building screens. Loadings (wind uplift, live loads, snow) and associated fixings to system components were investigated and built into the design from an early stage. Rapid prototypes were created in order to agree on a suitable cap projection and clip mechanism prior to material production. Collaboration on the design of this feature cap allowed the architects to see how the intersection between horizontal and vertical elements would look and quality/ease of machining on the profile.

Over the past few years, AHMM and Lend Lease have been reinventing the entire educational campus with a series of built interventions and outdoor spaces that respect the modernist principles of the original 1950’s buildings designed by Sir Leslie Martin. This led to Burntwood School winning the RIBA National Awards 2015.

Whatever the project and requirements, working in partnership with manufacturers and suppliers that can provide products of the right quality means that architects are able to deliver differentiation which will help them to stand out in the market, whether this is in terms of better service levels, performance guarantees, hardware aesthetics or security and energy performance.