Spiralling heights

Designed by the renowned architecture firm Skidmore, Owings & Merrill, Baltimore Tower rises 450 feet into Canary Wharf’s iconic skyline. Due for completion in 2016, this new residential development will offer executive suites and exclusive one, two and three bedroom apartments set in a visually stunning tower with a unique curving form. Each prestige property boasts a bespoke design, with sophisticated interiors and its own generously-sized private balcony, enabling residents to enjoy panoramic views over the capital.

Do the twist

The balconies’ axial rotation on the tower plan produces the building’s distinctive flowing twist. From levels two to 37, the apartment arrangement remains identical with the exception of the outer balcony ‘ring’. This shifts and steps by nominal degrees, reaching its furthest point to the right at level 13, where it then starts twisting its return to the centre line (at level 23) and then continues to its furthermost point on the left at levels 44 and 45. In addition to creating a visual spectacle, this architectural concept also provides variable solar shading and cover for each floor level.

Balustrades for integrated balconies to apartments in Baltimore Tower are being manufactured by Sapphire using its Crystal frameless, structural glass system, which offers clean, continuous lines and no vertical support posts to impede views for residents. The project’s challenging specification involves 1,200 tonnes of glass for balcony balustrades and glass floors. Sapphire is producing around 10,000 structural glass panels – 220 per floor – to form the faceted glass balustrades, which create the desired elliptical shape without the time and cost associated with curved glass.

In addition, etched glass panels supplied by Sapphire are providing privacy screens between individual apartment balconies at Baltimore Tower. Sapphire has also developed a new base fixing method to enable rapid installation of balustrades which, once installed, are completely concealed. In the nose, or extremity, of the oval ring beam, triple laminated obscured glass panels will be set into the balcony decks to produce the prestigious glass floors which form a creative feature that twists around the building.

Complex construction

Sapphire’s marketing manager Nick Haughton says complex balcony and balustrade projects like Baltimore Tower present many logistical challenges, due primarily to the scale of the operation, so it is critical that the supplier can achieve the demanding requirements.

“From our experience, there are two fundamentally important elements in creating major iconic buildings like Baltimore Tower,” he explains. “Firstly, there is the application of intelligent engineering in order to achieve the architect’s aesthetic vision and also to ensure the design meets the project’s functional and technical requirements, from BS EN standard compliance to replacement strategies.”

Haughton believes the second major factor is ensuring the chosen supplier has the ability to deliver on its promises at each stage of the project, from programme planning and procurement to manufacturing and just-in-time delivery. “In terms of the latter, Sapphire’s service has been aptly described by one of UK’s largest developers as the ability to ‘parachute in and out’ at exactly the right time,” he said.

Proactive approach

Strict supply management is playing a crucial role in achieving the exacting site schedules at Baltimore Tower. Sapphire is working to a programme agreed at the start of the project last year, which sets out exactly where and during which weeks the team will be working on site. By maintaining closely controlled stock levels of key components and close liaison with the main contractor and critical path suppliers, Sapphire is able to meet a two-week rolling programme of installing balconies floor by floor. By the end of June 2015, balcony balustrades, totalling 600 tonnes of glass, had been installed up to level 23 of the building. All the remaining glass required to complete the project is held in storage by Sapphire ready for call-off as and when required. Haughton says this supply approach has two key benefits: “Having the glass available ex-stock means we can schedule deliveries to site with precision timing. It also ensures consistency and continuity of product across the entire installation.”

Intelligent engineering

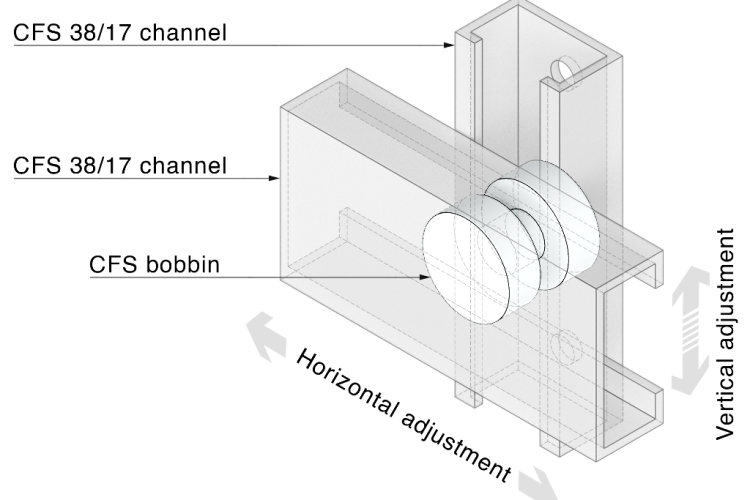

Installing balcony balustrades is carefully planned and coordinated with other trades to achieve best-in-class performance, often against tight deadlines. Site efficiency, and safety, is enhanced by a screening system, which has been developed by Sapphire as an alternative to traditional scaffolding on high-rise residential projects like Baltimore Tower. The system is designed to save contractors both the time and cost of erecting and dismantling scaffolding. It also helps ensure the safety of installers without the need for harnesses through the use of a ‘creeping shroud’ concept, which moves up the outside of the tower, starting at the lowest level and working up the building.

During the two-week rolling programme, Sapphire’s installation team and the main contractor work in tandem to optimise deliveries to site and the use of cranes on site.

“We sequence our works around each of the concrete pours,” said Haughton. “Having moved the safety screen to the level we’ll be working on next, glass stillages for balustrades to that floor arrive on site. The glass is then craned up ready for us to start installing,” he adds. Once the delivery vehicle is unloaded it is used to take away empty stillages from site, thereby optimising transport logistics for greater efficiency and a reduced carbon footprint.

Summing up, Haughton says a challenging balustrade project like Baltimore Tower highlights the importance of good programme planning and communication between project partners. “From our experience,” he says, “this process should start at the earliest possible stage to ensure designs are achievable and the proposed timescales for manufacturing and installation are workable for all those involved in delivering a successful project.”