Viega provides fitting solution to new residential development

Viega’s press connection technology has been specified for the Panorama development, a collection of studio suites and one-bedroom apartments in the heart of Uxbridge. Installed by Zero Carbon Solutions, the Viega press connection systems have been used on the hot and cold water services and heating system within the luxury flats.

Viega’s press connection technology has been specified for the Panorama development, a collection of studio suites and one-bedroom apartments in the heart of Uxbridge. Installed by Zero Carbon Solutions, the Viega press connection systems have been used on the hot and cold water services and heating system within the luxury flats.

Due to tight project deadlines and the need to avoid delays to following trades, the speed and ease of installation of the pipework is said to have been key. While press connections were the preferred choice to fulfill this requirement, Zero Carbon was initially reluctant to adopt this methodology due to leakage issues with other manufacturers’ press systems.

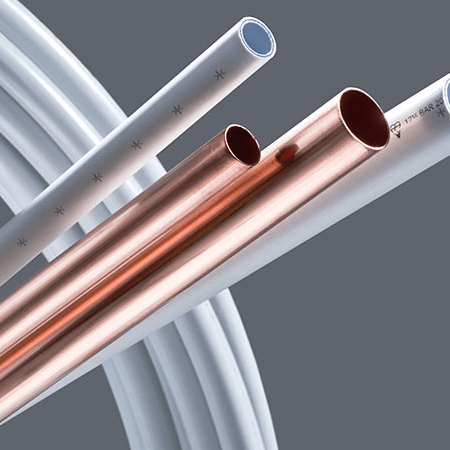

Following discussions with Zero Carbon about the project and its concerns, Plumbase Industrial recommended the Viega range including Profipress, Megapress and the latest addition to the range ¬– Megapress S XL.

Features of the Viega system such as its SC-Contur technology are said to have helped to reassure the team of the reliability of the connections. The patented SC-Contur includes a flow channel path within the fitting to ensure that any unintentionally missed connections are detected during leak testing. According to Viega, this means expensive and costly remedial work is avoided.

The specification for the heating system included the use of thick walled steel tube to provide improved durability. Viega’s unique Megapress system allows thick walled tube to be press connected, avoiding the time-consuming and messy process of cutting a thread onto each section of tube.

The heating distribution system also required an 80mm (3 inch) tube for which the new Megapress S XL innovation was selected. The press connection system is said to provide up to an 80% time saving compared with welding.

In addition to this, the cold-applied press connections are said to have eliminated the need for any hot works and subsequent cool down period, further reducing the time spent ensuring compliance on site.

Adam Robson, operations director at Zero Carbon Solutions, said: “We’re really impressed with the Viega press connection products. It’s a great solution that we’ve been recommending to customers – in fact, we are using them again on another development.”

Aaron Breeden, contracts manager at Zero Carbon Solutions who managed the project, said: “The Megapress and Profipress products saved ample time on site, and provided a quick and clean installation for our team. It is a simple process of placing the fitting onto the pipe, placing the press tool around it and squeezing the trigger. If any connections were mistakenly missed, it was easy to see and rectify with the SC-Contur feature. We found this incredibly helpful and reassuring.”